Cracked sewer pipes can be more than just a costly repair - they can result in extensive and pricey property damage and lead to serious health risks. Sewer linings can help repair cracked pipes without having to completely replace your sewer lines or destroy the area around them.

If you are looking to replace an existing underground sewer pipe that has started to leak, first consider your options. A full sewer replacement may not be necessary. Often times, relining your pipes is a better and more cost-effective solution. If your underground sewer lines are beneath trees, near extensive landscaping, sidewalks, driveways, or other semi-permanent features, total sewer excavation can cause a great deal of collateral damage, not to mention expense, to the surrounding area.

In many cases commercial property owners are able to get away with just relining their pipes. There are four types of pipe relining systems to get the job done right. All the materials will rehabilitate the interior of your pipes without having to completely replace them.

Here are the types of pipe relining systems available today :

1. Cured in place pipe lining (CIPP) :

Cured in place pipe lining, also known as CIPP lining, is a method of trenchless pipe restoration used in existing pipe repair. This process is done to preserve the current pipes that have been damaged by leaks, cracks, intruding roots, and rust. It increases the lifespan of a pipe system for up to 100 years while also possibly preserving the building structures and causing little to no damage to the property.

2. Cured in Place Point Repair :

Cured in place point repair is similar to CIPP lining just done on a smaller scale. This method repairs sections of pipes utilizing the same technique and process as CIPP lining. This method is ideal for pipes with only a few sections of pipe damage.

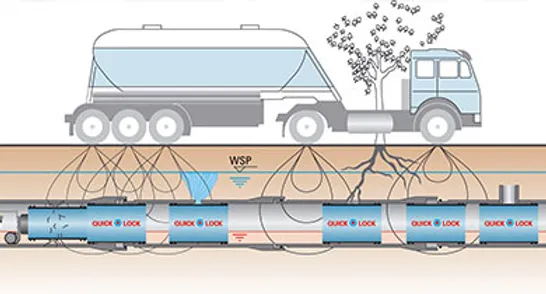

3. QuickLock Point Repair :

The QuickLock point pipe repair system is constructed of a 316L stainless steel sleeve structural body, covered by a seamless EPDM compression seal. QuickLock sleeves can be installed with flow present due to the fact that the packer is hollow, allowing for the flow pass through. The QuickLock point pipe repair can be easily be installed with no cure time, because no resin is involved. Through the manhole, the sleeve is inserted into the pipe and delivered to the damaged section. The sleeve is mechanically compressed against the inner pipe wall. Using an inflatable packer, the sleeve is then expanded and permanently locked into position.

4. Sliplining :

Sliplining is one of the oldest methods of trenchless pipe rehabilitation of existing pipelines. It is used to repair leaks or restore structural stability to an existing pipeline. It is completed by installing a smaller, "carrier pipe" into a larger "host pipe", grouting the annular space between the two pipes, and sealing the ends. The most common material used to slipline an existing pipe is high-density polyethylene (HDPE), but fiberglass-reinforced pipe (FRP) and PVC are also common.

5. Internal Pipe Coating :

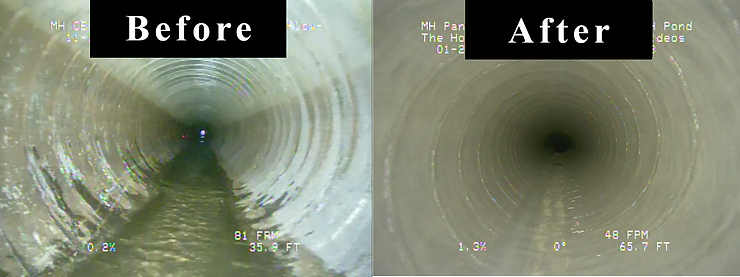

Professional installers use internal pipe coating to repair an existing sewer pipe that has started to leak into surrounding soil. To prepare the area for treatment, they will completely drain the pipes to get rid of any water. A thick epoxy coating is sprayed on the inside of your pipes to permanently seal the leaks and cracks throughout the pipeline.

All of these pipe relining techniques leave behind a smooth, seamless pipe that is designed to last for generations. We here at Wind River Environmental are here for all your sewer pipe relining needs. Call us today, to find out which service would be more beneficial or get a free quote on any of the services we offer. Find out why we are the leading company for pipe rehabilitation.